- introduce

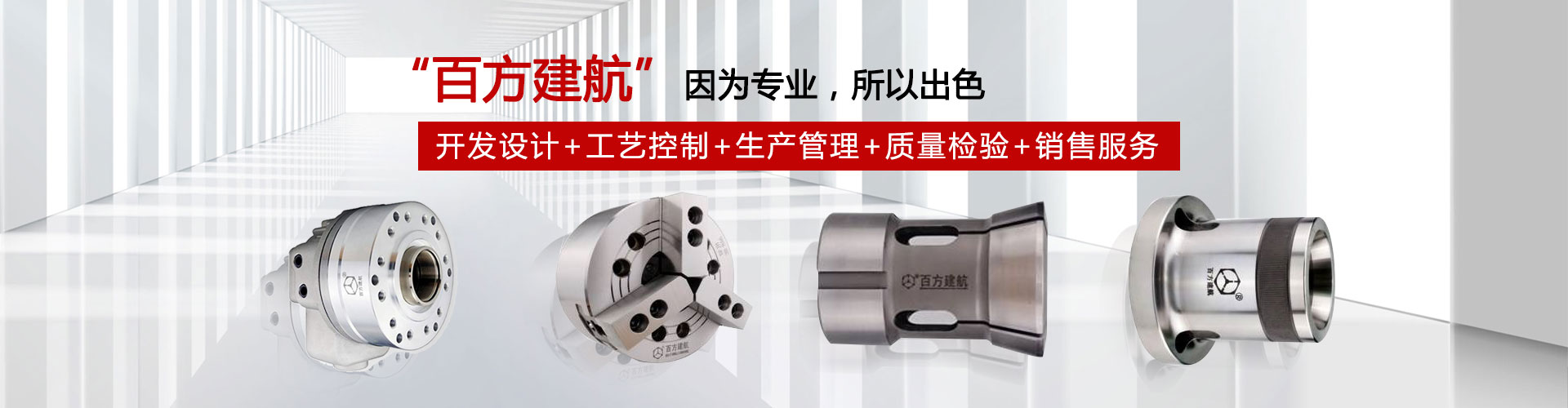

Around us, there are many CNC lathe chuck manufacturers, mainly because we often use CNC lathe chuck. CNC car chuck as one of the professional manufacturers, the long-term production and supply of spring chuck, cylinder clamp, CNC car clamp head a variety of related products, each product production has its own excellent characteristics, also has a certain range of use.

Through the introduction of relevant personnel, it is known that the usage rate of elastic chuck has increased rapidly in the past two years, which is nearly one million times higher than that of two years ago. With the continuous rise of small processing industry, the quality and precision of processing is undoubtedly the biggest competition object in the current market, and the emergence of this kind of cylinder clip, to some extent, has become the key to the survival of small and medium-sized enterprises. CNC car chuck in its regular use, the most used is er11-er25, accounting for this kind of collet 9/10. The annual output is about 350 million sets, in the field of drilling chuck share of the large, amazing. Hope that through the introduction of these knowledge, can play a corresponding help for the majority of users.

For the use of CNC car chuck to be able to smoothly, and can achieve the best use effect, the first thing to master is the correct method of operation, for the characteristics of CNC car chuck and its function we know, but for its correct operation you know how much?

This problem related professionals, for us to make a believe that the CNC car chuck is often a unique structure, a multi-purpose. When in use, first put the chuck into the pressure cap, gently rotate the clamping spring, the eccentric part of the pressure cap is concave into the clamping spring groove, and push the clamping spring evenly along the direction of the arrow to break the cone. And the CNC car chuck only need to move the sliding sleeve, can make drilling, tapping sleeve rapid replacement. When drilling, Morse sleeve automatically locked; When tapping, torque overload can smoothly slip and avoid the tap breaking. In addition, when changing the knife, loosen the pressure cap with a wrench to take out the chuck and tool, remove the tool, along the direction of the arrow to force the spring, make it out, and then according to the need to change other aperture spring can be.