- introduce

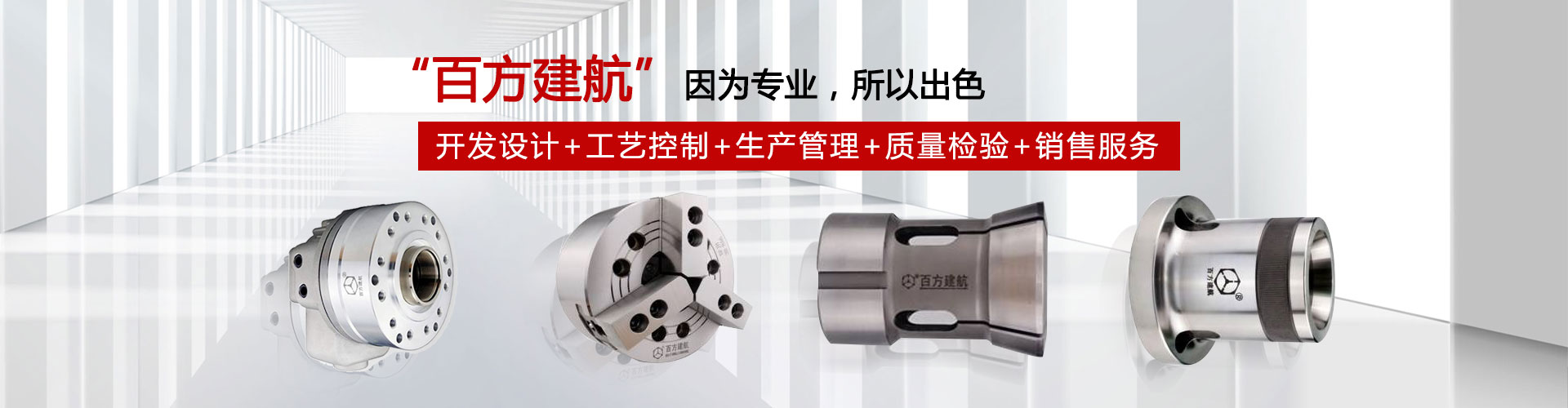

With the continuous development of science and technology, now the use of CNC lathe chuck is more and more widely, we have a certain understanding of CNC lathe chuck, CNC lathe chuck by the use of spring steel production, the accuracy is guaranteed, the knife type precision can be guaranteed within 0.01-0.015. CNC lathe chuck accessories and types are there? The following CNC lathe chuck manufacturers to introduce.

CNC lathe chuck USES: widely used in various types of CNC, instrument lathe, automatic lathe, etc

CNC lathe chuck and lathe accessories products

1, high precision spindle chuck for automatic lathe, back shaft chuck, guide sleeve, feeder material clip

2, inside hole square, hexagonal and other special-shaped pieces of high precision spindle chuck, back shaft chuck, guide sleeve, feeder material clip

3, with eccentricity of high precision spindle chuck, back shaft chuck

4. High precision spindle chuck and backshaft chuck with lengthened tip

5, non-standard drawing to sample customized high precision chuck

6, (chuck) hole is round, square, hexagonal, shaped, spring steel, hard alloy, and standard concentric, eccentric (chuck)

7, CNC chuck common class accuracy 0.005mm and high precision class HP class 0.003mm series

For the use of CNC car chuck to be able to smoothly, and can achieve the best use effect, the first thing to master is the correct method of operation, for the characteristics of CNC car chuck and its function we know, but for its correct operation you know how much?

This problem related professionals, for us to make a believe that the CNC car chuck is often a unique structure, a multi-purpose. When in use, first put the chuck into the pressure cap, gently rotate the clamping spring, the eccentric part of the pressure cap is concave into the clamping spring groove, and push the clamping spring evenly along the direction of the arrow to break the cone. And the CNC car chuck only need to move the sliding sleeve, can make drilling, tapping sleeve rapid replacement. When drilling, Morse sleeve automatically locked; When tapping, torque overload can smoothly slip and avoid the tap breaking. In addition, when changing the knife, loosen the pressure cap with a wrench to take out the chuck and tool, remove the tool, along the direction of the arrow to force the spring, make it out, and then according to the need to change other aperture spring can be.